The textile industry has witnessed remarkable transformations over the past century, yet few materials have maintained their relevance as consistently as rayon fabric. This versatile semi-synthetic fiber continues to capture the attention of manufacturers, designers, and consumers worldwide due to its unique blend of natural origins and engineered properties. Understanding what drives the popularity of rayon fabric in today's competitive apparel market reveals insights into both consumer preferences and manufacturing efficiency trends that shape the modern fashion landscape.

Manufacturing Advantages of Rayon in Modern Production

Cost-Effective Production Processes

Manufacturing facilities worldwide have embraced rayon fabric production due to its economically viable processing requirements. Unlike pure silk or high-end natural fibers, rayon offers manufacturers the ability to create luxurious-feeling textiles without the premium costs associated with natural fiber cultivation and harvesting. The controlled production environment allows for consistent quality standards while maintaining competitive pricing structures that appeal to both budget-conscious and premium market segments.

The streamlined manufacturing process of rayon fabric enables efficient scaling operations, making it particularly attractive for large-volume apparel production. Modern facilities can adjust production parameters to create various rayon grades, from lightweight summer garments to heavier winter wear, without requiring completely different manufacturing setups. This flexibility translates into reduced overhead costs and improved profit margins for textile manufacturers across different market tiers.

Quality Control and Consistency Benefits

Contemporary rayon fabric production offers manufacturers unprecedented control over fiber characteristics, enabling consistent quality delivery that natural fibers cannot always guarantee. The controlled manufacturing environment eliminates many variables that affect natural fiber quality, such as weather conditions, soil quality, and harvesting timing. This predictability allows apparel manufacturers to maintain consistent product standards across different production batches and seasonal collections.

Advanced quality control systems in rayon fabric manufacturing facilities ensure that each batch meets specific tensile strength, colorfastness, and dimensional stability requirements. These standardized properties enable apparel manufacturers to predict garment performance accurately, reducing quality-related returns and enhancing brand reputation. The ability to engineer specific characteristics into rayon fabric during production provides manufacturers with customization options that align with particular garment requirements and target market expectations.

Consumer Appeal and Market Demand Factors

Comfort and Wearability Characteristics

The exceptional comfort properties of rayon fabric have established its position as a preferred choice among consumers seeking breathable, soft-touch garments. The fiber's natural moisture-wicking capabilities and temperature regulation properties make it particularly suitable for various climate conditions and active lifestyles. Unlike synthetic alternatives that may trap heat and moisture, rayon fabric allows air circulation while maintaining the luxurious feel that consumers associate with premium textiles.

Modern consumers increasingly prioritize comfort in their clothing choices, driving demand for fabrics that offer all-day wearability without compromising style or appearance. Rayon fabric delivers this balance by providing the drape and flow characteristics of silk while maintaining the practical benefits of engineered fibers. The fabric's ability to move with the body while retaining its shape makes it ideal for both casual wear and professional attire, expanding its market appeal across diverse consumer segments.

Versatility in Fashion Applications

The adaptability of rayon fabric across different fashion categories has contributed significantly to its sustained popularity in apparel manufacturing. From flowing summer dresses to structured blazers, rayon demonstrates remarkable versatility in accepting various finishing treatments and construction techniques. This flexibility allows designers to incorporate rayon fabric into diverse garment types without compromising their creative vision or functional requirements.

Fashion brands appreciate rayon fabric's excellent dyeability and print receptiveness, enabling vibrant colors and intricate patterns that maintain their appearance through multiple wash cycles. The fiber's compatibility with both digital and traditional printing methods provides manufacturers with cost-effective options for creating distinctive designs that capture consumer attention in competitive retail environments. This design flexibility, combined with the fabric's inherent elegance, positions rayon as a strategic material choice for brands targeting style-conscious consumers.

Environmental Considerations and Sustainability Trends

Renewable Resource Utilization

The growing emphasis on sustainable manufacturing practices has highlighted rayon fabric's advantages as a material derived from renewable cellulose sources. Unlike petroleum-based synthetic fibers, rayon originates from wood pulp and other plant materials, aligning with consumer preferences for environmentally conscious textile choices. This renewable foundation appeals to environmentally aware consumers and supports brand sustainability initiatives that have become increasingly important in competitive markets.

Modern rayon fabric production facilities have implemented advanced processing methods that reduce environmental impact while maintaining product quality standards. Closed-loop production systems recover and reuse processing chemicals, minimizing waste generation and reducing the overall environmental footprint of rayon manufacturing. These improvements address earlier environmental concerns associated with rayon production and position the fabric as a more sustainable alternative to traditional synthetic materials.

Biodegradability and End-of-Life Benefits

The biodegradable nature of rayon fabric provides significant advantages in addressing growing concerns about textile waste and circular economy principles. Unlike synthetic fibers that persist in landfills for decades, rayon fabric naturally decomposes under appropriate conditions, reducing long-term environmental impact. This characteristic supports sustainable fashion initiatives and appeals to consumers who consider the complete lifecycle of their clothing purchases.

Manufacturers increasingly recognize the marketing value of promoting biodegradable materials as part of their environmental responsibility programs. The ability to communicate genuine sustainability benefits associated with rayon fabric helps brands differentiate themselves in markets where environmental consciousness influences purchasing decisions. This positioning advantage becomes particularly valuable as regulatory requirements and consumer expectations continue to evolve toward greater environmental accountability in textile production.

Technical Performance and Innovation Developments

Enhanced Durability Through Modern Processing

Contemporary rayon fabric production incorporates advanced processing techniques that significantly improve durability characteristics compared to traditional manufacturing methods. Modern treatments enhance the fiber's resistance to shrinkage, pilling, and color fading, addressing historical concerns about rayon fabric performance in demanding applications. These improvements expand the material's suitability for garments requiring frequent washing and extended wear cycles.

Innovative finishing processes applied to rayon fabric during manufacturing create enhanced performance characteristics without compromising the material's natural feel and appearance. Anti-microbial treatments, wrinkle resistance, and improved dimensional stability represent significant advances that make rayon competitive with synthetic alternatives in performance-oriented applications. These technical improvements broaden the market opportunities for rayon fabric across diverse apparel categories and consumer segments.

Blending Capabilities and Composite Materials

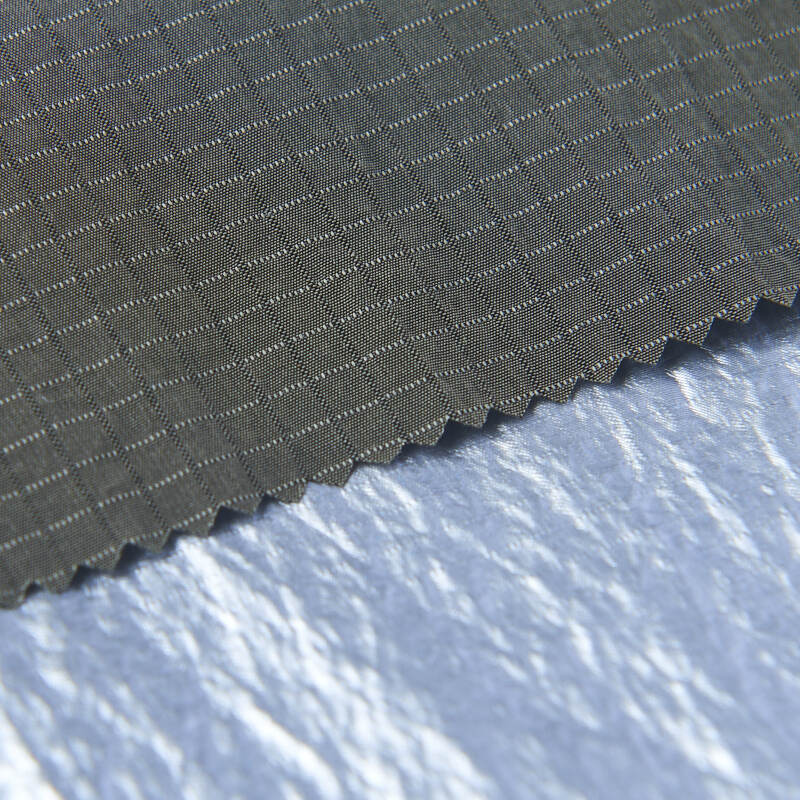

The exceptional blending characteristics of rayon fabric enable manufacturers to create composite materials that optimize performance attributes while maintaining cost effectiveness. Strategic blending with cotton, polyester, or specialty fibers allows manufacturers to engineer specific properties such as enhanced stretch, improved moisture management, or increased durability. These blending capabilities provide flexibility in meeting diverse market requirements without completely redesigning manufacturing processes.

Advanced blending techniques with rayon fabric create opportunities for developing innovative textile solutions that address specific consumer needs or market gaps. The compatibility of rayon with various fiber types enables manufacturers to balance natural comfort characteristics with engineered performance features, creating products that appeal to consumers seeking both luxury feel and practical functionality. This versatility in material engineering supports product differentiation strategies and enables competitive positioning in specialized market segments.

Global Supply Chain and Market Accessibility

Reliable Sourcing and Production Networks

The established global supply chain for rayon fabric provides manufacturers with reliable access to consistent material supplies, supporting predictable production planning and inventory management. Unlike some natural fibers subject to seasonal availability or regional production limitations, rayon fabric manufacturing operates on consistent schedules that align with apparel industry demand cycles. This reliability reduces supply chain risk and enables manufacturers to maintain steady production flows.

International production networks for rayon fabric offer manufacturers flexibility in sourcing strategies, enabling cost optimization while maintaining quality standards. The availability of multiple suppliers across different regions provides resilience against localized disruptions and supports competitive pricing negotiations. This supply chain stability particularly benefits manufacturers operating in fast-fashion segments where rapid response times and cost control significantly impact profitability and market competitiveness.

Scalability and Volume Production Capabilities

Modern rayon fabric production facilities demonstrate impressive scalability that supports both small-batch specialty applications and high-volume mass market requirements. The ability to adjust production volumes efficiently enables manufacturers to respond effectively to market demand fluctuations without significant operational disruptions. This scalability advantage supports both established brands with predictable volume requirements and emerging companies with variable production needs.

The standardized nature of rayon fabric production processes facilitates knowledge transfer and capacity expansion across different manufacturing locations. This standardization enables consistent quality delivery regardless of production facility location, supporting global manufacturing strategies and supply chain optimization initiatives. The ability to maintain consistent rayon fabric characteristics across multiple production sites provides manufacturers with operational flexibility while ensuring product quality consistency that consumers expect from established brands.

FAQ

What are the main advantages of rayon fabric in garment manufacturing

Rayon fabric offers numerous advantages in garment manufacturing, including cost-effective production processes, excellent drape characteristics, and superior dyeability. The material provides manufacturers with consistent quality control while offering consumers comfort properties similar to natural fibers at more accessible price points. Additionally, rayon fabric's versatility enables its use across diverse apparel categories, from casual wear to formal garments, making it a strategic choice for manufacturers serving multiple market segments.

How does rayon fabric compare to natural and synthetic alternatives

Rayon fabric combines the best characteristics of natural and synthetic fibers while addressing many of their individual limitations. Compared to cotton, rayon offers superior drape and moisture-wicking properties, while providing better breathability than most synthetic alternatives. The material's biodegradable nature gives it environmental advantages over petroleum-based synthetics, while its consistent production quality surpasses the variability often associated with natural fibers. This balanced performance profile makes rayon fabric an attractive option for manufacturers seeking optimal cost-performance ratios.

What sustainability benefits does rayon fabric provide

Rayon fabric derives from renewable cellulose sources, primarily wood pulp, making it more environmentally sustainable than petroleum-based synthetic fibers. Modern production methods incorporate closed-loop systems that recover and reuse processing chemicals, significantly reducing environmental impact. The fabric's biodegradable nature ensures it does not contribute to long-term textile waste accumulation, supporting circular economy principles increasingly important to environmentally conscious consumers and regulatory frameworks.

How has rayon fabric technology evolved to meet modern market demands

Contemporary rayon fabric production incorporates advanced processing techniques that enhance durability, dimensional stability, and performance characteristics. Modern treatments provide improved resistance to shrinkage, pilling, and fading while maintaining the natural comfort properties that make rayon attractive to consumers. Innovation in blending capabilities enables manufacturers to create composite materials that optimize specific performance attributes, expanding rayon fabric applications across diverse market segments and specialized use cases.