The Evolution of Advanced Materials in Modern Industry

The landscape of industrial manufacturing has been revolutionized by the introduction and continuous development of synthetic fibers. These engineered materials have become the backbone of countless applications, from aerospace components to everyday consumer goods. Unlike natural fibers, synthetic fibers offer unprecedented control over material properties, enabling manufacturers to create products with exact specifications to meet demanding industrial requirements.

Today's synthetic fibers represent decades of materials science advancement, combining innovative chemical processes with cutting-edge manufacturing techniques. The result is a versatile class of materials that can be tailored for strength, durability, and specific performance characteristics that natural alternatives simply cannot match.

Superior Physical Properties of Engineered Materials

Exceptional Strength-to-Weight Ratios

One of the most compelling advantages of synthetic fibers lies in their remarkable strength-to-weight ratios. These engineered materials can deliver tensile strengths exceeding those of steel while maintaining a fraction of the weight. This characteristic makes synthetic fibers particularly valuable in applications where weight reduction is crucial, such as in automotive and aerospace industries.

Modern synthetic fibers can be engineered to provide specific strength profiles, with some varieties offering up to five times the strength of steel at just one-fifth the weight. This exceptional strength-to-weight ratio translates into improved fuel efficiency in transportation applications and reduced material requirements in structural components.

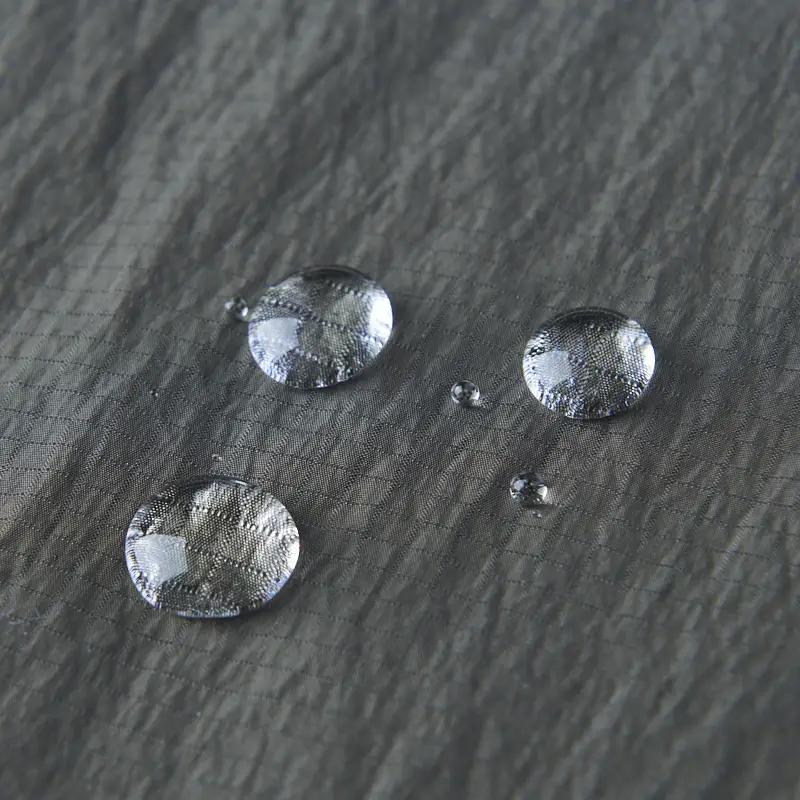

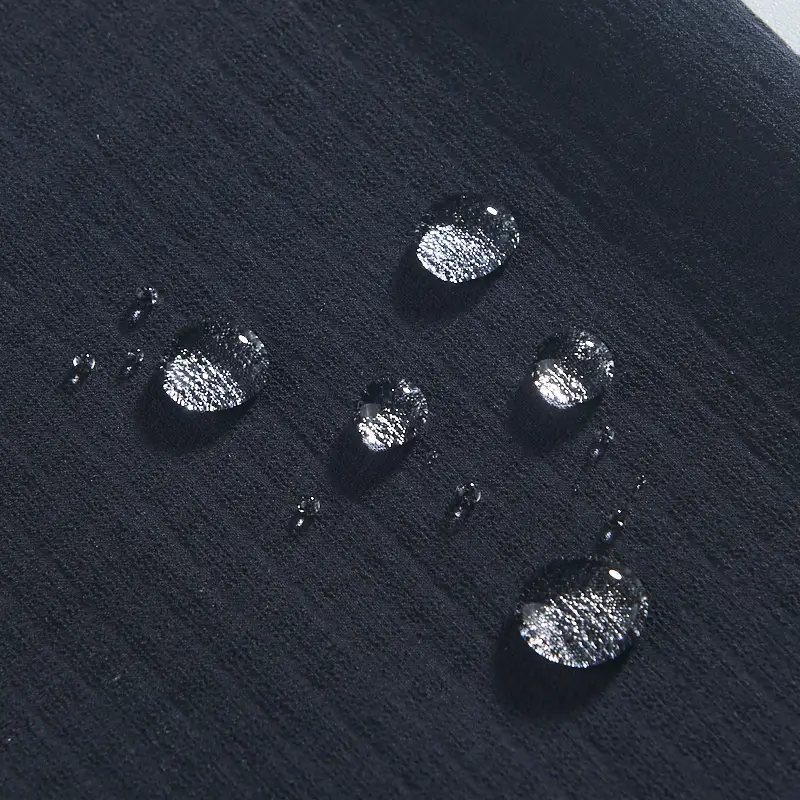

Temperature and Chemical Resistance

Industrial environments often expose materials to extreme conditions, and synthetic fibers excel in these challenging situations. Many synthetic fiber varieties maintain their structural integrity across a wide temperature range, from sub-zero conditions to several hundred degrees Celsius. This thermal stability is complemented by excellent chemical resistance, making synthetic fibers ideal for use in corrosive environments.

The chemical structure of synthetic fibers can be modified to resist specific types of degradation, whether from acids, bases, or organic solvents. This adaptability ensures longevity in applications where natural fibers would quickly deteriorate, resulting in significant cost savings over time.

Manufacturing Versatility and Process Control

Customizable Production Parameters

The manufacturing process for synthetic fibers offers unprecedented control over material properties. By adjusting parameters such as molecular weight, crystallinity, and fiber diameter, manufacturers can precisely tune the characteristics of the final product. This level of control ensures consistency across production batches and enables the creation of application-specific materials.

The ability to manipulate these variables during production allows for the development of synthetic fibers with optimized properties for particular industrial applications. Whether the requirement is for high elasticity, minimal creep, or specific optical properties, the manufacturing process can be adjusted accordingly.

Scalable Production Methods

Modern synthetic fiber production facilities can operate continuously, producing large volumes of material with consistent quality. This scalability is crucial for industrial applications, where reliable supply chains and consistent material properties are essential. The automated nature of synthetic fiber production also helps reduce costs while maintaining high quality standards.

Advanced manufacturing techniques, such as melt spinning and solution spinning, allow for the production of fibers with various cross-sectional shapes and surface textures. This versatility in manufacturing processes enables the creation of specialized synthetic fibers for specific industrial applications.

Environmental Performance and Sustainability

Durability and Lifecycle Benefits

While synthetic fibers are often criticized for their environmental impact, their durability and long service life can actually contribute to sustainability. Industrial applications of synthetic fibers typically result in products that last significantly longer than those made with natural alternatives, reducing the frequency of replacement and associated resource consumption.

The extended lifecycle of synthetic fiber products often translates into lower environmental impact when considered over the entire use period. Additionally, many synthetic fibers can be recycled or repurposed at the end of their primary use, further extending their useful life.

Emerging Eco-Friendly Innovations

The synthetic fiber industry is actively developing more sustainable production methods and materials. Bio-based synthetic fibers, produced from renewable resources, are becoming increasingly viable for industrial applications. These innovations maintain the performance advantages of traditional synthetic fibers while reducing environmental impact.

Research into closed-loop manufacturing systems and chemical recycling processes is advancing the sustainability profile of synthetic fibers. These developments are crucial for industries seeking to reduce their environmental footprint while maintaining high performance standards.

Frequently Asked Questions

How do synthetic fibers compare to natural fibers in industrial applications?

Synthetic fibers generally offer superior strength, durability, and consistency compared to natural fibers in industrial applications. They can be engineered for specific performance requirements and maintain their properties more reliably under harsh conditions. While natural fibers may have advantages in certain applications, synthetic fibers typically provide better overall performance in demanding industrial environments.

What are the most common types of synthetic fibers used in industry?

The most widely used synthetic fibers in industrial applications include polyester, nylon, aramid fibers, and carbon fibers. Each type has specific advantages: polyester offers excellent dimensional stability, nylon provides high tensile strength, aramid fibers deliver exceptional heat resistance, and carbon fibers combine lightweight properties with superior strength.

Are synthetic fibers cost-effective for industrial use?

While the initial cost of synthetic fibers may be higher than natural alternatives, they often prove more cost-effective over time due to their longer lifespan, reduced maintenance requirements, and superior performance characteristics. The total cost of ownership, including maintenance and replacement costs, typically favors synthetic fibers in industrial applications.

Can synthetic fibers be customized for specific industrial applications?

Yes, synthetic fibers can be extensively customized during the manufacturing process to meet specific industrial requirements. Properties such as strength, elasticity, chemical resistance, and thermal stability can be adjusted by modifying the chemical composition, molecular structure, and processing conditions of the fibers.