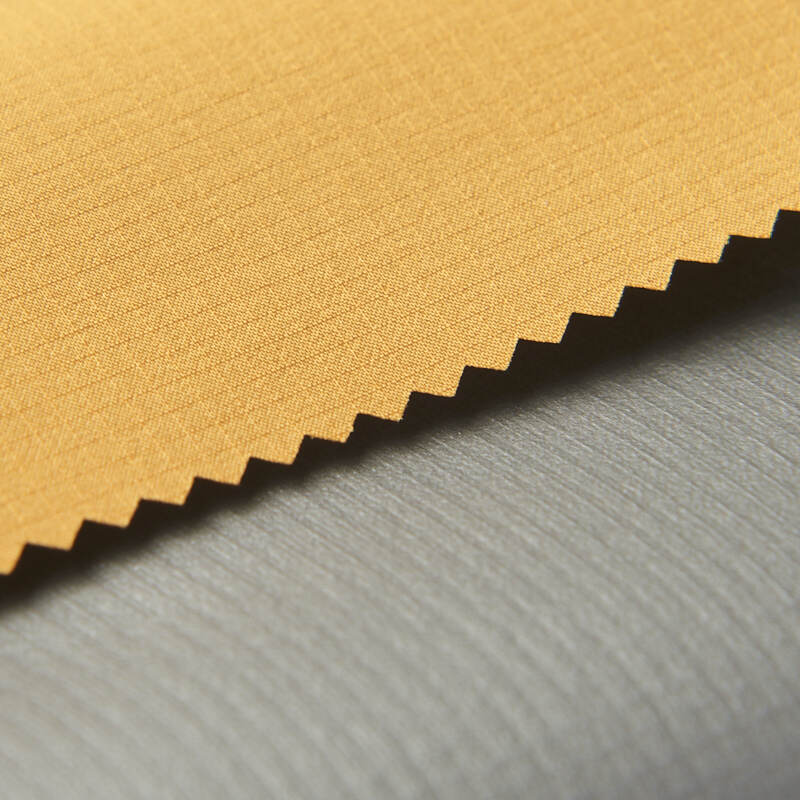

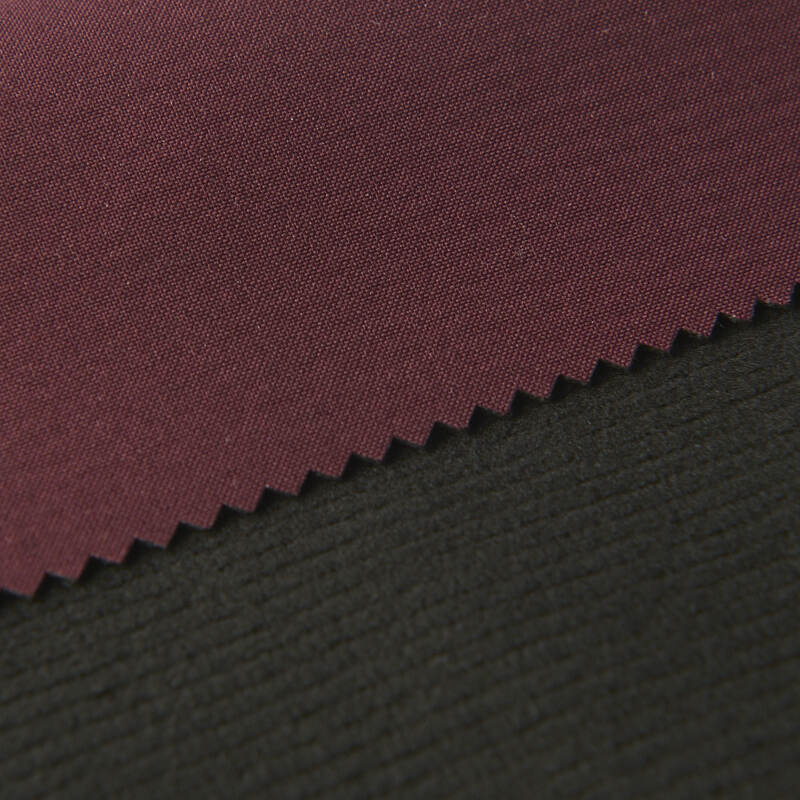

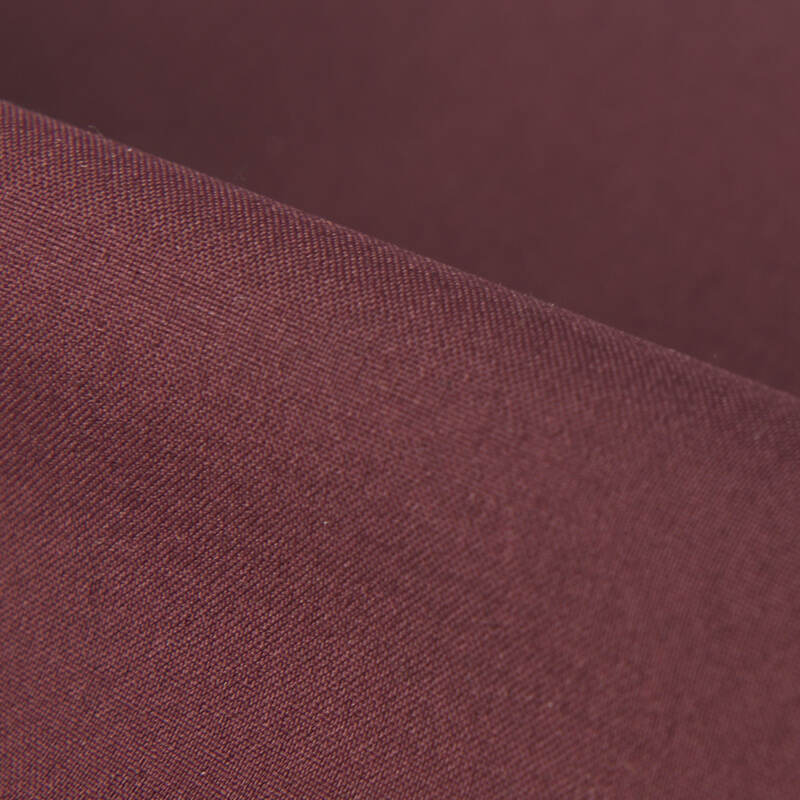

produsen kain tahan bocor

Seorang produsen kain anti-bocor bulu (downproof) mengkhususkan diri dalam menciptakan tekstil berkinerja tinggi yang dirancang secara khusus untuk mencegah bulu-bulu halus (down feathers) menembus material tersebut. Fasilitas khusus ini menggunakan teknologi tenun canggih dan proses akhir inovatif untuk menghasilkan kain yang ditenun rapat dengan sifat penghalang luar biasa. Proses manufaktur melibatkan pemilihan serat berkualitas tinggi serta penerapan teknik penenunan yang presisi guna menciptakan konstruksi kain yang sangat ketat dengan ukuran pori minimal. Hal ini memastikan kain mampu menahan isian bulu secara efektif sekaligus mempertahankan sifat bernapasnya. Fasilitas modern produksi kain anti-bocor bulu menggunakan peralatan mutakhir untuk mencapai kontrol kualitas yang konsisten, dilengkapi metode pengujian canggih untuk memverifikasi tingkat ketahanan terhadap bulu sesuai standar industri. Proses produksi juga mencakup perlakuan khusus yang meningkatkan daya tahan dan karakteristik kinerja kain, seperti ketahanan terhadap air dan angin. Fasilitas ini umumnya menerapkan kontrol kualitas yang ketat di seluruh rantai produksi, mulai dari pemilihan bahan baku hingga pengujian produk akhir, sehingga setiap batch memenuhi spesifikasi ketat terkait kemampuan menahan bulu, kenyamanan, dan daya tahan. Keahlian produsen juga mencakup pengembangan solusi khusus untuk berbagai aplikasi, termasuk pakaian outdoor, perlengkapan tempat tidur, dan peralatan teknis khusus.