water repellent fabric supplier

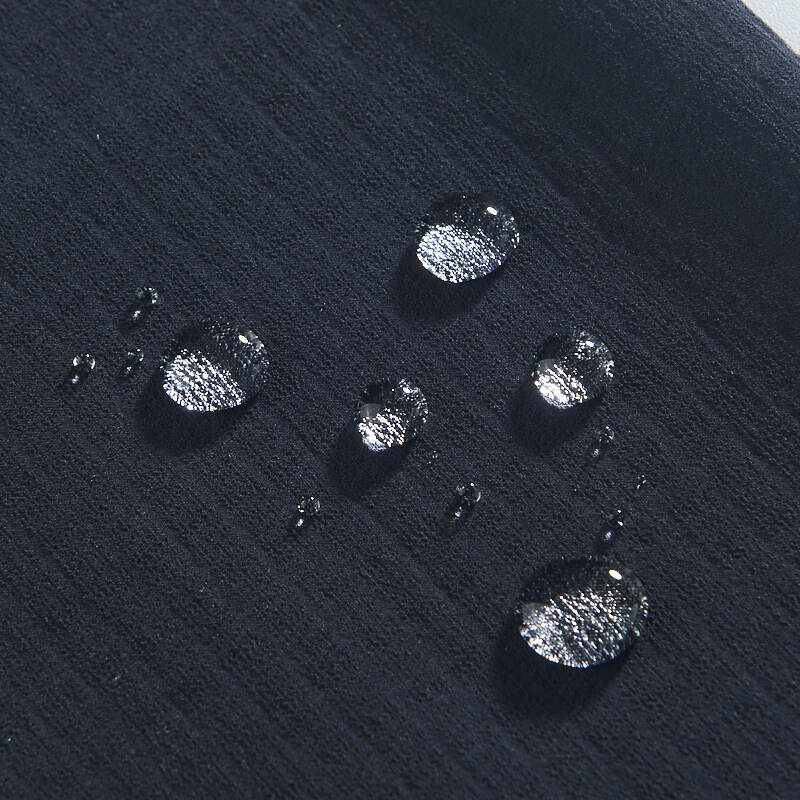

A water repellent fabric supplier stands as a crucial partner in the textile industry, offering innovative solutions for manufacturers and businesses seeking high-performance materials. These suppliers specialize in providing fabrics treated with advanced water-repellent technologies, ensuring that materials maintain their protective properties while remaining breathable and comfortable. The suppliers utilize cutting-edge DWR (Durable Water Repellent) treatments and other specialized coating processes to create fabrics that effectively repel water, oils, and various liquids while maintaining the material's original texture and flexibility. Their product range typically includes both natural and synthetic fabrics, treated with eco-friendly water repellent solutions that meet international environmental standards. These suppliers serve diverse industries, from outdoor apparel and sportswear to technical textiles and protective equipment. They maintain strict quality control measures throughout the production process, ensuring consistent performance and durability of their water repellent treatments. Additionally, many suppliers offer customization options, allowing clients to specify the level of water repellency, fabric weight, and other technical parameters to meet specific application requirements.