Paano Sintetikong serbo Pahabain ang Buhay ng Modernong Telang

Nakilala ang Keyword: synthetic fibers

Patuloy na nagbabago ang mundo ng tela habang hinahanap ng mga manufacturer ang mga tela na mas mahusay ang pagganap, mas matibay, at makakatipid ng pera sa ilalim ng panahon. Nangingibabaw ang sintetikong hibla bilang isa sa mga pinakamalaking pag-unlad sa mga nakaraang dekada. Hindi tulad ng mga natural na hibla na galing nang diretso sa mga halaman o hayop, ang sintetiko ay ginawa gamit ang mga proseso sa kemikal sa mga laboratoryo at pabrika. Ang mga man-made na hiblal na ito ay nagdudulot ng natatanging mga katangian sa mga telang gumagawa ng mas matibay at mas mahirap isuot. Mula sa sportswear na nakakapaglaban sa matinding pag-eehersisyo hanggang sa mga kagamitang panglabas na nakakatagpo ng pinsala dulot ng panahon, binago ng sintetikong materyales ang mga posibilidad sa pagmamanupaktura ng tela sa libu-libong mga industriya.

Mga Structural na Benepisyo ng Synthetic Fibers

Matibay na Tensile Strength at Resilience

Ang mga synthetic na hibla ay idinisenyo upang makatiis ng mataas na stress, na nagbibigay ng mga telang mahusay na tensile strength. Ang mga materyales tulad ng nylon at polyester ay lumalaban sa paghila at pagkabasag nang mas mahusay kaysa maraming natural na hibla. Ang pagtutol na ito ay partikular na mahalaga sa mga aplikasyon sa industriya, activewear, at muwebles, kung saan ang mga tela ay nakakaranas ng madalas na alitan at pagkastress.

Pare-parehong Istraktura ng Hibla para sa Pantay na Tibay

Ang mga natural na hibla ay may posibilidad na magkaroon ng iba't ibang uri ng pagkakaiba-iba sa kapal at lakas mula sa isang hibla patungo sa isa pa, samantalang ang mga sintetiko ay ginagawa ayon sa eksaktong mga sukat. Dahil sobrang pagkakatulad nila, ang mga artipisyal na hiblang ito ay nagpapakalat ng kanilang lakas ng pantay-pantay sa buong tela, na nangangahulugan na walang mga random na parte kung saan maaaring bigyan ng paraan ang materyales. Ito ay nagdudulot ng malaking pagkakaiba sa mga damit na suot natin araw-araw pati na rin sa mga gamit sa mga pabrika at lugar ng konstruksyon. Karamihan sa mga tao ay nakakapansin na ang kanilang mga sintetikong damit na pantrabaho ay mas tumatagal kahit pagaraan ng ilang buwan kumpara sa mga alternatibo na katulad ng cotton o lana.

Resistensya sa Mga Stressor ng Kapaligiran

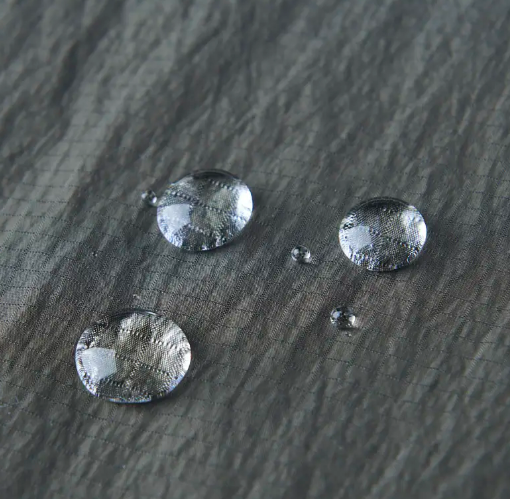

Ang Paglaban sa Kada Balot ay Nakakapigil sa Pagkasira ng Tela

Mayroon silang natatanging katangian ang sintetikong hibla pagdating sa pagtutol sa kahalumigmigan. Hindi gaanong natataba ng kahalumigmigan ang mga ito kumpara sa ibang materyales. Iyon ang dahilan kung bakit ang mga tela na gawa sa sintetikong hibla ay mas nakakatolera sa mga problema dulot ng amag, mantsa, at pagkabulok, lalo na sa mga lugar na may mataas na kahalumigmigan o malapit sa tubig. Kumuha tayo ng halimbawa sa koton, isang natural na hiblang nakakainom ng kahalumigmigan parang b sponge. Sa paglipas ng panahon, maaaring maging sanhi ito upang maging mahina at hindi magtagal ang tela. Dahil mas matagal na natatagpuang tuyo, ang mga damit na gawa sa sintetikong hibla ay mainam na gamitin sa labas o saanman kailangan ang proteksyon laban sa pinsala ng tubig. Gustong-gusto ng mga manufacturer ang katangiang ito sa paggawa ng mga kagamitang kailangang magperform sa mahihirap na kondisyon nang hindi nababasag.

UV Stability para sa Matagalang Paggamit sa Labas

Ang ilang mga sintetikong fibers ay nakakatanggap ng espesyal na pagtrato upang hindi masira sa ilalim ng UV light, na isang bagay na talagang nakasisira sa mga natural na materyales sa paglipas ng panahon. Kumuha ng akrilik at polyester para sa halimbawa, ang mga tela na ito ay kadalasang may built-in na proteksyon laban sa UV, na ginagawa silang mahusay na pagpipilian para sa mga bagay tulad ng muwebles sa bakuran, layag ng bangka, o kahit na mga kagamitan sa kamping na kailangang tumagal laban sa sikat ng araw. Ano ang nagpapahalaga sa tampok na ito? Mahaba ang panahon na mukhang maganda ang mga produktong gawa sa mga fibers na ito, nananatiling matibay at nagpapanatili ng kanilang orihinal na kulay sa halip na maging palaubaya o mawarped pagkatapos ng ilang buwan sa labas.

Bawasan ang Paggamit ng Friction at Paulit-ulit na Paglalaba

Napabuti ang Lumaban sa Pagkasayad

Ang mga sintetikong fibers ay maaaring tumagal ng isang malaking pag-atake nang walang mga palatandaan ng pagkalat kapag sinasabit sa mga mabagyo o paulit-ulit na sinasagutan. Ang kakayahang labanan ang pag-abrasion ay gumagawa ng mga materyales na ito na mainam para sa mga produkto na kinakaharap ang pang-araw-araw na parusa, isipin ang mga strap ng backpack na nag-aalis sa balikat, mga uniporme ng militar na hinihila sa buong lupa, o kagamitan sa konstruksiyon na nalant Kapag ang mga gumagawa ay nagsasama ng mga bagay na tulad ng nailon o ang matigas na fibers ng aramid sa kanilang mga tela, sila ay nagtatapos sa mga tela na patuloy na tumatagal ng mahabang panahon matapos ang mas murang mga alternatibo ay magsisimula na maghiwalay sa ilalim ng katulad na paggamot.

Kakayahang Panatilihin ang Sukat Matapos Hugasan

Ang mga likas na hibla ay madalas na nangangasiwa o nawawalan ng hugis pagkatapos ng maramihang paglalaba. Bilang pagbabago, ang mga sintetikong hibla ay mas nakakapagpanatili ng kanilang sukat, kahit pagkatapos ng paulit-ulit na paglaba. Ang pagkakatibay sa sukat na ito ay nagsisiguro na ang mga damit ay mananatiling akma, hugis, at gumagana nang maayos sa paglipas ng panahon, nagpapataas ng kanilang naaangking kalidad at pinalalawig ang kanilang magagamit na habang-buhay.

Pagpapasadya para sa Tiyak na Pangangailangan sa Pagganap

Mga Dinisenyong Halo para sa Pinagsamang Lakas

Maraming tela ngayon ang nagkakombina ng sintetiko at natural na hibla upang ika-ekwilbryong komport sa tibay. Halimbawa, ang cotton-polyester blends ay nag-aalok ng kahabaan ng cotton kasama ang lakas at pagtutol sa pagkabagot ng polyester. Ang mga ganitong blends ay karaniwang ginagamit sa pang-araw-araw na damit at uniporme, kung saan mahalaga ang kaginhawaan at tibay.

Mga Kemikal na Paggamot Upang Palakasin ang Tibay

Sintetikong serbo maaaring gamutin ng kemikal na pangwakas upang higit pang mapabuti ang kanilang pagganap. Ang mga anti-pilling na paggamot ay binabawasan ang pagbuo ng surface fuzz, samantalang ang mga stain-resistant na patong ay nagpoprotekta sa mga tela mula sa karaniwang mga silyo. Ang mga pagpapahusay na ito ay nagpapahaba sa telang malinis na itsura at pag-andar, lalo na sa mga propesyonal o mataong kapaligiran.

Mga Aplikasyon sa Mahihirap na Sektor

Industriyal at Teknikal na Mga Gamit

Ang mga lugar ng konstruksyon, eroplano, at kotse ay umaasa sa sintetikong tela para mapanatili ang kaligtasan ng mga manggagawa at tibay ng kagamitan. Kumuha ng halimbawa ang Kevlar at Nomex, ang mga materyales na ito ay ginawa upang makatagal laban sa mga bagay na sasabog sa ilalim ng matinding init mula sa apoy o di tuwirang trauma sa pag-atake nang hindi nagiging salansan. Ang tunay na mundo ay patuloy na nagpapatunay sa puntong ito. Ang mga bombero ay suot ang gear na gawa sa mga hibla dahil ang koton ay hindi gagana sa isang apoy. Katulad nito, ang mga drayber ng karera ng kotse ay umaasa sa kanila upang mabuhay sa mga aksidente na sasabog sa karaniwang materyales. Kapag nasa panganib ang buhay, ang mga sintetiko ay simpleng gumagawa ng hindi kayang gawin ng likas na hibla.

Sportswear at Outdoor Gear

Ang damit-panlaro at kagamitan ay nangangailangan ng mataas na tibay nang hindi nasisiyahan ang kaginhawaan. Hindi lamang mas magaan ang mga hibla na sintetiko kundi mas matatagasan at matibay din kumpara sa mga natural na alternatibo. Pinagsamang kalidad na ito ay nagpapalawig ng paggamit sa mga mapanganib na kapaligiran, kaya ito ang pinakamainam na pagpipilian para sa mga hiker, atleta, at manggagawa sa labas.

Pansariling Pag-uugnay at Pag-recycle

Mas Matagal na Paggamit ay Nagbaba ng Kabuuang Konsumo

Ang mga sintetikong fibers ay may mga isyung pangkapaligiran sa panahon ng pagmamanupaktura, ngunit mas matibay ito kaysa sa mga natural na alternatibo, na nangangahulugang mas kaunti lang ang damit na binibili ng mga tao sa paglipas ng panahon. Kapag ang mga damit ay nananatiling maong para sa maraming taon at hindi lang para sa isang panahon, nabawasan ang bilang ng mga bagong damit na ginagawa at sa huli ay itinatapon. Ang mga kumpanya na seryosong naghahanap ng mga paraan para maging mapanatili ay nakakapansin na rin ng ugnayang ito. Ang matibay na mga materyales ay talagang umaangkop sa mga modernong paraan ng eco-friendly na disenyo dahil binabawasan nito ang paulit-ulit na proseso ng produksyon at pagtatapon na karaniwan sa industriya ng moda ngayon.

Mga Pag-unlad sa Recyclability

Ang mga bagong teknolohiya ay nagpapabuti sa pagrecycle ng mga sintetikong tela. Ang mga materyales tulad ng recycled polyester (rPET) ay nagbibigay ng pangalawang buhay sa mga ginamit na bote ng plastik at basura mula sa industriya, na ginagawang mataas ang kalidad ng tela. Ang mga pag-unlad na ito ay nagpapahusay sa pagiging angkop ng sintetikong fiber sa mga linya ng produktong may pangangalaga sa kalikasan at sa mga sistema ng closed-loop.

FAQ

Ano ang nagpapahusay sa tibay ng sintetikong fiber kaysa sa natural na fiber?

Ang mga sintetikong fiber ay may disenyo na molekular na istraktura na nagbibigay ng mataas na tensile strength, resistensya sa pagkasayad, at pagtutol sa mga epekto ng kapaligiran, na nagpapahusay sa kanilang tibay sa iba't ibang kondisyon.

Ang mga sintetikong tela ay lagi bang mas mahusay para sa pangmatagalang paggamit?

Bagaman ang mga sintetikong tela ay karaniwang mas matibay, ang pinakamahusay na pagpipilian ay nakadepende sa aplikasyon. Halimbawa, ang cotton ay maaaring mas mainam para sa paghinga, ngunit ang mga sintetikong fibers ay perpekto para sa lakas at paglaban sa pagsusuot.

Maaari bang i-recycle ang mga sintetikong tela?

Oo, ang ilang mga sintetikong tela tulad ng polyester ay maaaring i-recycle, lalo na kung idinisenyo na may recyclability sa isip. Ang mga recycled sintetikong fibers ay bawat araw na ginagamit sa mga eco-friendly textiles.

Naglalaban ba ang mga sintetikong fibers sa pagkawala ng kulay at pag-urong?

Maraming mga sintetikong fibers ang naglalaban sa pagkawala ng kulay dahil sa sikat ng araw at pag-urong dahil sa paglalaba, upang mapanatili ang itsura at pagganap ng tela sa paglipas ng panahon.

Talaan ng Nilalaman

- Paano Sintetikong serbo Pahabain ang Buhay ng Modernong Telang

- Mga Structural na Benepisyo ng Synthetic Fibers

- Resistensya sa Mga Stressor ng Kapaligiran

- Bawasan ang Paggamit ng Friction at Paulit-ulit na Paglalaba

- Pagpapasadya para sa Tiyak na Pangangailangan sa Pagganap

- Mga Aplikasyon sa Mahihirap na Sektor

- Pansariling Pag-uugnay at Pag-recycle

- FAQ